Your problem:

- You want to manufacture series or individual components for a laboratory device, an electronic device or similar from ceramics?

- You need high-quality ceramic spare parts?

- Your current suppliers no longer manufacture ceramic insulators?

- The ceramic moulds are in need of repair or have been lost?

- Tool refurbishing isn’t worthwhile or is too expensive?

Unfortunately, glass, porcelain or steatite are only suitable to a limited extent for solving these problems.

The ideal material for it is called:

STUMATIT

We are configured to manufacture workpieces for you – from complicated individual manufacturing up to small series.

STUMATIT is a natural stone! (pyrophyllite, AL-silicate).

The raw material is available from us in blocks of 260 x 260 x 260mm.

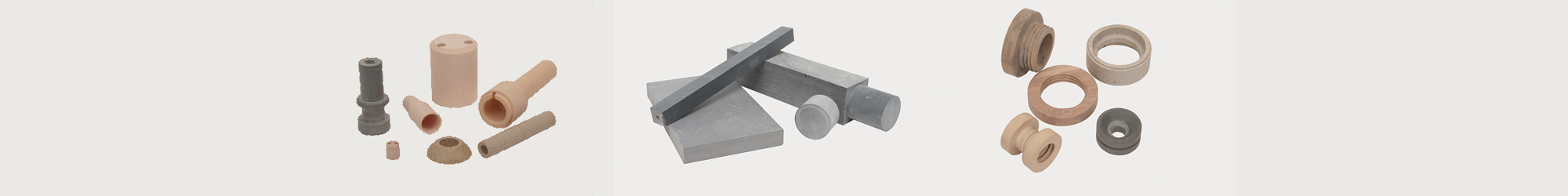

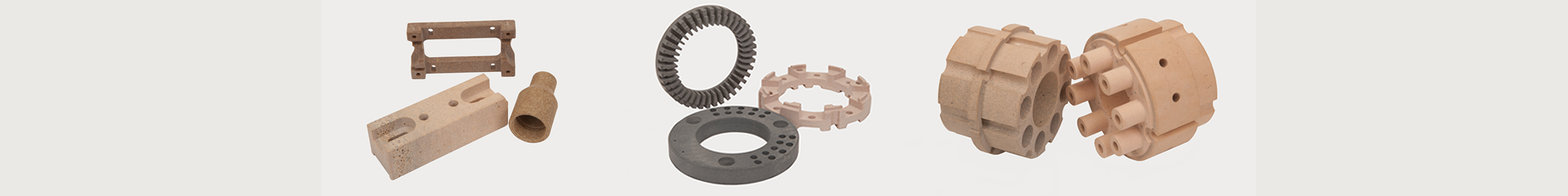

It can be used in accordance with your specifications to manufacture all shapes (waves, squares, discs, finished parts, etc.).

Advantages of STUMATIT:

- Lowest loss when burning!

- High resistance to wear

- Chemical resistance to most acids and alkaline solutions

- No expensive tools or moulds required

- Complex shaping realisable in small series

- Drilling, milling, turning, filing

- Narrower tolerances possible, like for comparable ceramic materials

- Sharp-edged, dimensionally stable contours

- Glazing of workpieces possible

OUR STRENGTHS:

- The raw material is available with a maximum size of 260 x 260 x 260mm

- Adapted, optimum infrastructure – attractive prices therefore possible

- Short communication routes provide clarity and efficiency

- Adapted manufacturing processes, own kilns, fast delivery times!

Ask us – we are happy to help you